|

|

|

|

|

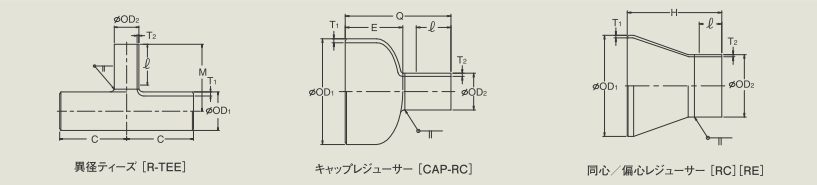

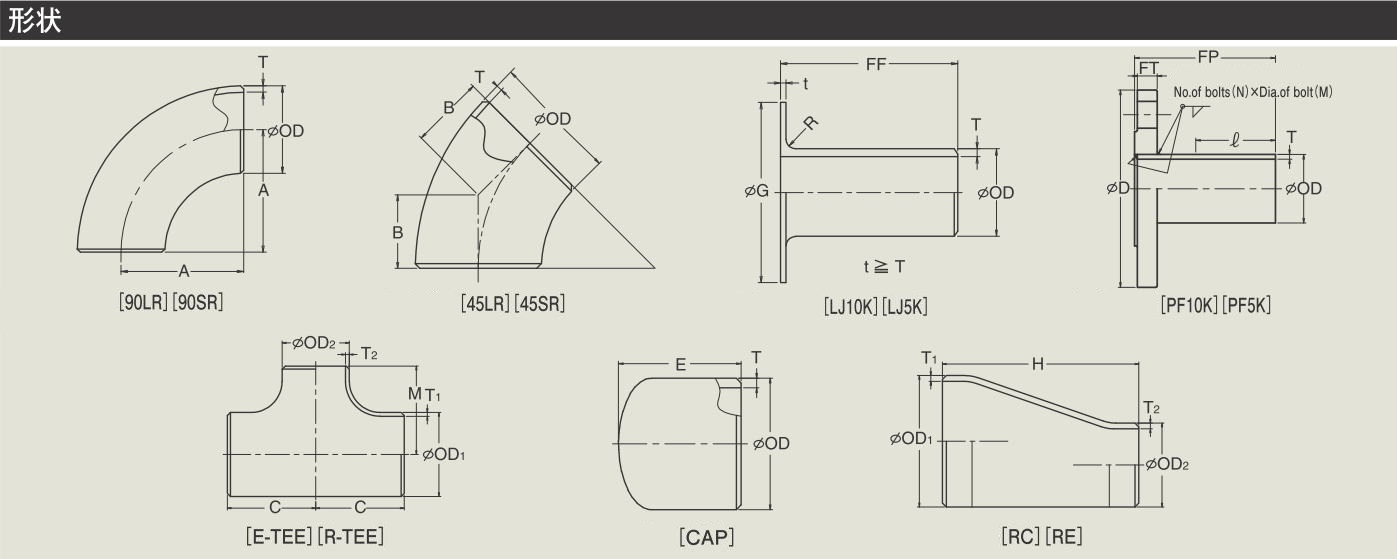

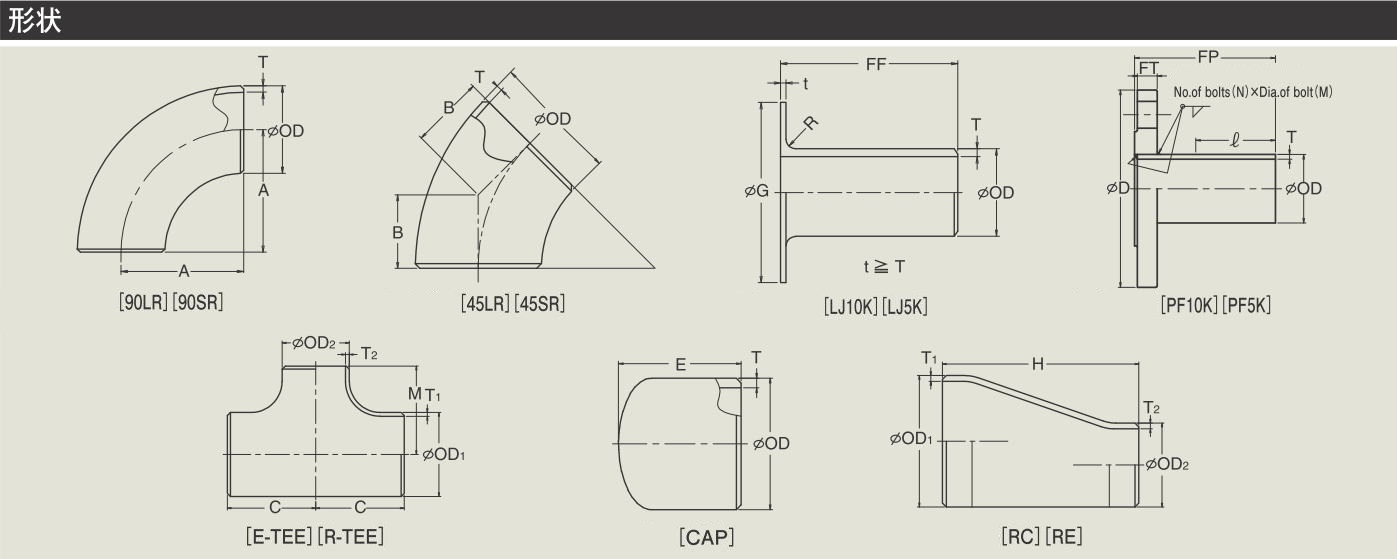

MANUAL-WELDING FITTINGS

Table D-1: Dimensions

|

Nominal

pipe size |

Long elbow

[90LR]

[45LR]

|

Short elbow

[90SR]

[45SR]

|

Lap joint JPF10K

[LJ10K]

|

Pipe flange

[PF10K]

[PF

5K]

|

JIS

10K flange

[JIS

10K FL] |

|

OD

|

A

|

B

|

A

|

B

|

FF

|

G

|

R

|

FP

|

D

|

FT

|

N

|

M

|

|

125A

|

190.5

|

78.9

|

127.0

|

52.6

|

50

|

182

|

5

|

85 |

250

|

20

|

8

|

M20

|

|

150A

|

228.6

|

94.7

|

152.4

|

63.1

|

50

|

212

|

5

|

90 |

280

|

22

|

8

|

M20

|

200A

|

304.8

|

126.2

|

203.2

|

84.2

|

65

|

262

|

5

|

90 |

330

|

22

|

12

|

M20

|

|

250A

|

381.0

|

157.8

|

254.0

|

105.2

|

65

|

324

|

5

|

100 |

400

|

24

|

12

|

M22

|

|

300A

|

457.2

|

189.4

|

304.8

|

126.2

|

65

|

368

|

5

|

120 |

445

|

24

|

16

|

M22

|

|

350A

|

533.4

|

220.9

|

355.6

|

147.3

|

75

|

413

|

5

|

120 |

490

|

26

|

16

|

M22

|

|

400A

|

609.6

|

252.5

|

406.4

|

168.3

|

75

|

475

|

5

|

120 |

560

|

28

|

16

|

M24

|

Table D-2: Dimensions

|

Nominal

pipe size

|

Equal tee

[E-TEE]

|

Cap

[CAP]

|

Nominal sizes

of

branch

pipe and smal end

|

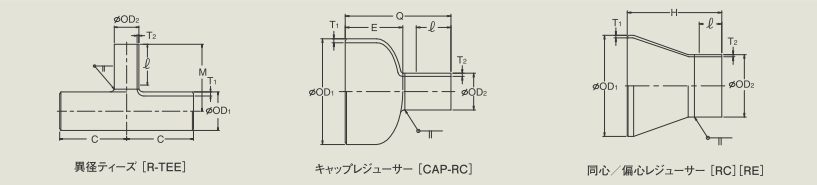

Reducing tee

[R-TEE]

|

Cap reducer

[CAP-RC]

|

Concentric,

Eccentric reducer

[RC][RE]

|

|

OD (OD1)

|

C=M

|

E

|

OD2

|

C

|

M

|

Q

|

H

|

|

125A

|

123.8 |

76.2 |

|

|

|

|

127.0 |

|

150A

|

142.9 |

88.9 |

125A

|

142.9 |

136.5 |

(170) |

139.7 |

200A

|

177.8 |

101.6 |

125A

|

177.8 |

161.9 |

(180) |

152.4 |

|

150A

|

168.3 |

|

250A

|

215.9 |

127.0 |

125A

|

215.9 |

190.5 |

210 |

177.8 |

|

150A

|

193.7 |

|

200A

|

203.2 |

|

|

300A

|

254.0 |

152.4 |

125A

|

254.0 |

215.9 |

240 |

203.2 |

|

150A

|

219.1 |

|

200A

|

228.6 |

|

|

250A

|

241.3 |

|

350A

|

279.4 |

165.1 |

150A

|

279.4

|

238.1 |

250 |

330.2 |

|

200A

|

247.7 |

270 |

|

250A

|

257.2 |

|

|

300A

|

269.9 |

|

400A

|

304.8 |

177.8 |

150A

|

304.8 |

263.5 |

260 |

355.6 |

|

200A

|

273.1 |

280 |

|

250A

|

282.6 |

|

|

300A

|

295.3 |

|

350A

|

304.8 |

|

|

|

|

|

Manual welding of large diameter side

Automatic welding of branch pipe/small diameter sides (with straight length

end) Fittings

Table D-3: Dimensions

|

Nominal

pipe size

|

Nominal sizes

of

branch

pipe and small end

|

Reducing tee

[R-TEE] |

Cap reducer

[CAP-RC]

|

Concentric,

Eccentric reducer

[RC][RE]

|

|

OD (OD1)

|

OD2

|

C

|

M |

Q

|

H

|

125A

Bevel end at mother pipe side |

50A |

120 |

130 |

140 |

190 |

| 100A, 80A, 65A |

140 |

140 |

- |

150A

Bevel end at mother pipe side |

100A, 80A |

150 |

160 |

- |

205 |

| 125A |

170 |

170 |

- |

200A

Bevel end at mother pipe side |

100A |

160 |

180 |

170 |

220 |

| 150A, 125A |

180 |

190 |

- |

| 250A |

8A,

1/2", 3/8", 1/4" |

110 |

180 |

170 |

|

| 25A, 20A, 15A, 10A, 1", 3/4" |

130 |

190 |

180 |

| 50A, 40A, 32A |

150 |

200 |

190 |

| 100A, 80A, 65A |

170 |

210 |

200 |

| 150A, 125A |

190 |

220 |

210 |

250 |

| 200A |

210 |

240 |

|

270 |

| 300A |

8A,

1/2", 3/8", 1/4" |

120 |

200 |

200 |

|

| 25A, 20A, 15A, 10A, 1", 3/4" |

140 |

210 |

210 |

| 50A, 40A, 32A |

160 |

220 |

220 |

| 100A, 80A, 65A |

180 |

230 |

230 |

| 150A, 125A |

200 |

240 |

240 |

280 |

| 200A |

220 |

260 |

|

300 |

| 350A |

8A,

1/2", 3/8", 1/4" |

130 |

220 |

210 |

|

| 25A, 20A, 15A, 10A, 1", 3/4" |

150 |

230 |

220 |

| 50A, 40A, 32A |

170 |

240 |

230 |

| 100A, 80A, 65A |

190 |

250 |

240 |

| 150A, 125A |

210 |

260 |

250 |

410(150A) |

| 200A |

230 |

280 |

270 |

430 |

| 400A |

8A,

1/2", 3/8", 1/4" |

130 |

250 |

220 |

|

| 25A, 20A, 15A, 10A, 1", 3/4" |

150 |

260 |

230 |

| 50A, 40A, 32A |

170 |

270 |

240 |

| 100A, 80A, 65A |

200 |

280 |

250 |

| 150A, 125A |

220 |

290 |

260 |

| 200A |

240 |

310 |

280 |

460 |

|

|

Please refer to common dimensions pages for

outside diameter (OD), thickness (T) and length (ℓ) of straight end length.

Manual-welding fittings below 100A and

from 350A to 900A are available. Please contact us.

Manual-welding elbows, reducers, caps and

tees are JIS B2312, 2313 specification products, and lap joints are JPF SP001

specification products, and flanges are JIS B2220 specification products. Their

dimensional tolerance is determined by the dimensional tolerance of

respectively applicable standard.

|

|

|

|